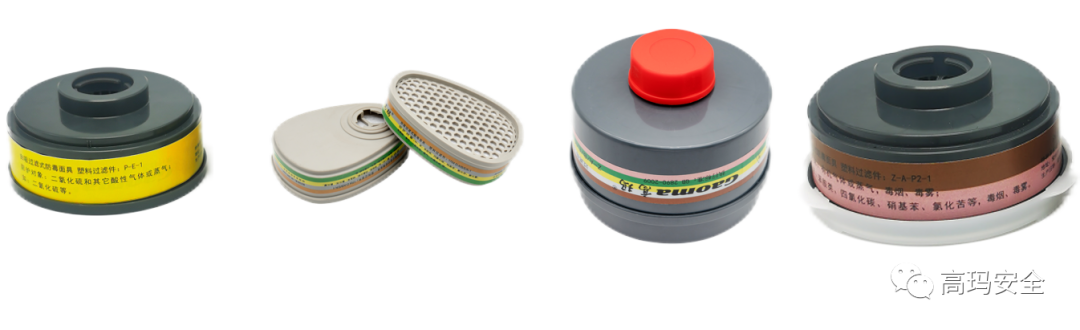

Gaoma Safety | How to determine the replacement cycle of the gas mask cartridge?

Release time:

2023-12-15

If you work in an environment that is exposed to harmful gases for long periods of time, Are you worried that your protective gear has failed? Are there frequent doubts about the replacement cycle of filter elements?

If you work in an environment that is exposed to harmful gases for long periods of time,

Are you worried that your protective gear has failed?

Are there frequent doubts about the replacement cycle of filter elements?

How to ensure the effectiveness of the use of gas masks is the basic requirement for the safety and responsibility of workers, and how to determine the replacement cycle of the filter box is a major issue that often puzzles users and even occupational protection experts!

At present, laws and regulations and industry norms do not give specific standards for reference, and the commonly used argument is to refer to the method of GBZ/T 195 Appendix G to calculate. However, in practical applications, due to the concentration of harmful substances in the workplace, temperature and humidity conditions, the wearer's breathing volume and other factors are not only different from the test condition, but also may change at any time, so that the effective use time of the filter box cannot be accurately estimated. If the use time is estimated according to linear conditions, the influence of different conditions must be considered, and it is best to have a safety factor. In particular, industrial enterprises in high-humidity areas along the eastern coast of China should pay special attention to the impact of the water content in the atmosphere on the filter box!

Because there are too many and complex factors affecting the adsorption capacity of the filter box, it is generally not to estimate the timing of the replacement of the filter box, it is best to use the detection instrument or the wearer's sense of smell to judge, the development of the detection instrument is still not perfect at this stage, and generally can only be judged by the wearer's sense of smell.

Goma security provides the judgment method is:

① First test whether the air tightness of the gas mask is good. If you block the inlet of the filter tank with the palm of your hand after wearing the mask, and then inhale hard, the mask will be squeezed inward towards the face due to the relationship of air pressure, indicating that the mask has been worn airtight, and no air leakage will occur.

② Enter the operation scene to see whether the smell of gas can still be smelled; Or whether there is a toxic reaction in the working environment under the condition of good wear and good air tightness to determine whether the filter box has failed.

The methods of applying the olfactory method to practical management are:

The employer manager will be the same nature of the work of the workers (preferably new employees, the reason is that the old workers for the workplace odor is likely to have smell paralysis, not as sensitive as the smell of new workers) to use the filter box time record, if someone found that the filter box failed, the same as the worker to use the same filter box all replacement, After the accumulation of these data, you can know the time that the type of work personnel use the filter box, and then use this time to manage, if the time is up, regardless of whether the wearer smells odor, it is replaced in time. If there is an odor within the specified time, the filter box should be replaced immediately.

With the continuous progress of science and technology, I believe that professional testing equipment will become more and more accurate; As a member of the labor insurance industry, Gaoma Safety will lead the R & D team to constantly explore and innovate, improve the detection method of the filter box, and strive to ensure the safety of the majority of workers!